Advertisement

At Hannover Messe 2025, Rockwell Automation drew crowds with the debut of its AI-powered digital twin technology, offering a smarter way for factories to see and solve problems before they happen. Rather than relying on static simulations, these digital twins utilize live data and machine learning to accurately mirror real-world conditions, minute by minute.

Visitors watched as virtual models instantly adapted to changes, predicting breakdowns, suggesting optimizations, and uncovering inefficiencies without guesswork. The demonstration demonstrated how manufacturing can become more precise and responsive, enabling businesses to experiment safely and improve performance without shutting down production or wasting resources.

Rockwell Automation's digital twins bring a fresh take to industrial simulation by combining machine learning with live operational data. Unlike older models that simply follow a set of fixed parameters, this system accurately reflects conditions as they truly are, even as they change over time. Traditional digital twins often fall short when machines age, workloads change, or unforeseen variables disrupt the plan. Rockwell's AI-driven approach constantly learns from incoming data, updating its virtual replica in real time and offering actionable suggestions the moment it detects something off.

The technology is remarkably adaptable, capable of representing anything from a single piece of equipment to an entire production facility. This level of flexibility allows operators to zoom in on specific inefficiencies or view how different processes interact as a whole. One standout feature is its ability to safely test "what-if" scenarios. Teams can try adjusting line speeds, rearranging workflows, or introducing new equipment virtually, observing the effects before making any changes in the real world. This minimizes disruption and maintains steady production while improvements are explored.

The system also excels in predictive maintenance. Instead of waiting for scheduled service or reacting to breakdowns, operators can spot early warning signs and address them before they become serious. This not only extends the lifespan of machinery but also saves on repairs and prevents unexpected stoppages that can derail production.

At Hannover Messe 2025, Rockwell demonstrated how its AI-powered digital twins could benefit a wide range of industries. Each example highlighted the adaptability of the technology and how it solves challenges unique to different manufacturing sectors.

In automotive production, manufacturers are using digital twins to reconfigure assembly lines for electric vehicles, testing layouts virtually to optimize output while maintaining quality standards. With changing consumer preferences and regulations driving rapid evolution in vehicle design, the ability to adjust quickly without halting production is a significant advantage.

Food and beverage processors showcased how the system helps maintain consistency in products that are sensitive to temperature, pressure, and timing variations. Simulating these delicate processes in the virtual environment minimizes waste and ensures batches meet exacting standards.

Pharmaceutical companies demonstrated the ability to maintain compliance with strict regulations by using the twin to monitor, document, and adjust production conditions. Since minor deviations can have serious consequences, having a constantly updated virtual model reduces risks while maintaining throughput.

Electronics manufacturers, who often deal with intricate components and tight tolerances, benefit from the digital twin’s predictive maintenance feature. By identifying early signs of wear or misalignment, they can prevent damage to expensive components and maintain production on schedule.

These examples illustrate how the same core technology can be tailored to diverse requirements, helping manufacturers in different fields meet their specific production and quality goals while staying flexible in the face of change.

While the launch of AI-powered digital twins generated excitement at Hannover Messe, some important considerations remain. At the heart of any such system is data, and the quality and completeness of that data directly influence how useful the twin can be. Inaccurate or incomplete data streams can lead to misleading predictions, which may cause more harm than good. Companies looking to implement this technology will need to ensure their sensors, networks, and data collection practices are up to the task.

Workforce preparedness is another factor. While Rockwell has worked to make the user interface approachable and intuitive, operators and engineers still need to understand how to interpret the system’s recommendations and integrate them into daily operations. Many facilities will need training programs to build this familiarity and avoid misusing or underusing the tool’s capabilities.

Cybersecurity remains a serious concern as well. Feeding sensitive operational data into a connected, intelligent platform opens up new avenues for potential attacks or breaches. Rockwell has emphasized built-in protections and secure communication protocols to mitigate these risks; however, companies will need to integrate these tools into their broader security strategies to effectively protect their operations.

These challenges are not insurmountable, but they do require deliberate planning and ongoing oversight to ensure that the technology delivers on its promise.

The unveiling of AI-powered digital twins at Hannover Messe 2025 signals a broader shift toward smarter, more adaptive production systems. Manufacturers have been under increasing pressure to produce more efficiently, respond faster to changes in demand, and meet stricter environmental and regulatory standards. Technology that can help predict problems, optimize processes, and reduce waste will likely play a central role in meeting those demands.

Rockwell’s solution brings together two powerful ideas — the digital twin and artificial intelligence — into a single platform that feels accessible to manufacturers of varying sizes and technical maturity. Rather than replacing human decision-making, the system is designed to support it, providing clearer insight into what’s happening on the factory floor and what actions are most likely to deliver better results.

For visitors at Hannover Messe 2025, the demonstrations served as a tangible glimpse into how these technologies are evolving beyond theory into practical tools. Rockwell Automation’s focus on adaptability and simplicity may help ease some of the hesitancy that often surrounds new digital technologies in manufacturing.

Rockwell Automation's AI-powered digital twins, unveiled at Hannover Messe 2025, mark progress toward smarter, more adaptive manufacturing. By combining machine learning with live data, the system generates dynamic virtual models that enhance visibility and inform decision-making. Industries from automotive to electronics benefit without added complexity. While data quality, workforce readiness, and security remain challenges, the technology promises efficient, reliable, and flexible operations, meeting demands for speed, accuracy, and sustainability while keeping processes simple and controlled.

Advertisement

How Gradio reached one million users by focusing on simplicity, openness, and real-world usability. Learn what made Gradio stand out in the machine learning community

Microsoft has introduced stronger safeguards and policies to tackle malicious Copilot AI use, ensuring the tool remains safe, reliable, and aligned with responsible AI practices

Ahead of the curve in 2025: Explore the top data management tools helping teams handle governance, quality, integration, and collaboration with less complexity

Learn the top 8 Claude AI prompts designed to help business coaches and consultants boost productivity and client results.

Advertisement

Bias in generative AI starts with the data and carries through to training and outputs. Here's how teams audit, adjust, and monitor systems to make them more fair and accurate

Tired of reinventing model workflows from scratch? Hugging Face offers tools beyond Transformers to save time and reduce boilerplate

Improve your skills (both technical and non-technical) and build cool projects to set yourself apart in this crowded job market

A leading humanoid robot company has introduced its next-gen home humanoid designed to assist with daily chores, offering natural interaction and seamless integration into home life

Advertisement

Curious about ChatGPT jailbreaks? Learn how prompt injection works, why users attempt these hacks, and the risks involved in bypassing AI restrictions

How the OpenAI jobs platform is changing the hiring process through AI integration. Learn what this means for job seekers and how it may reshape the future of work

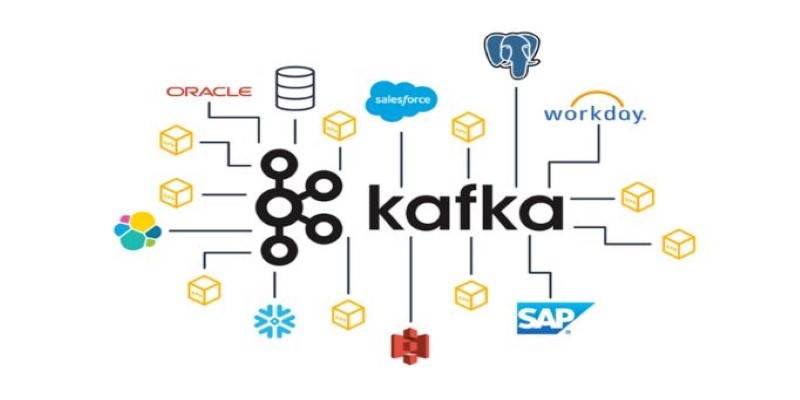

Explore Apache Kafka use cases in real-world scenarios and follow this detailed Kafka installation guide to set up your own event streaming platform

How Nvidia produces China-specific AI chips to stay competitive in the Chinese market. Learn about the impact of AI chip production on global trade and technological advancements